The standard difference between Metalcraft Distributors and gravity conveyors is that a Representative has a hoist system, whereas a Gravity Conveyor does not. The distinction also depends on the dimension of the hoist. A Metalcraft supplier has a flat bed like surface on the top which can be raised by rollers or wheels. This bed additionally limits the dimension of items that can be lugged in it. On the various other hand, a gravity conveyor has a lengthy bent metal slide that can suit heavy items without the requirement to move the real item along the surface.

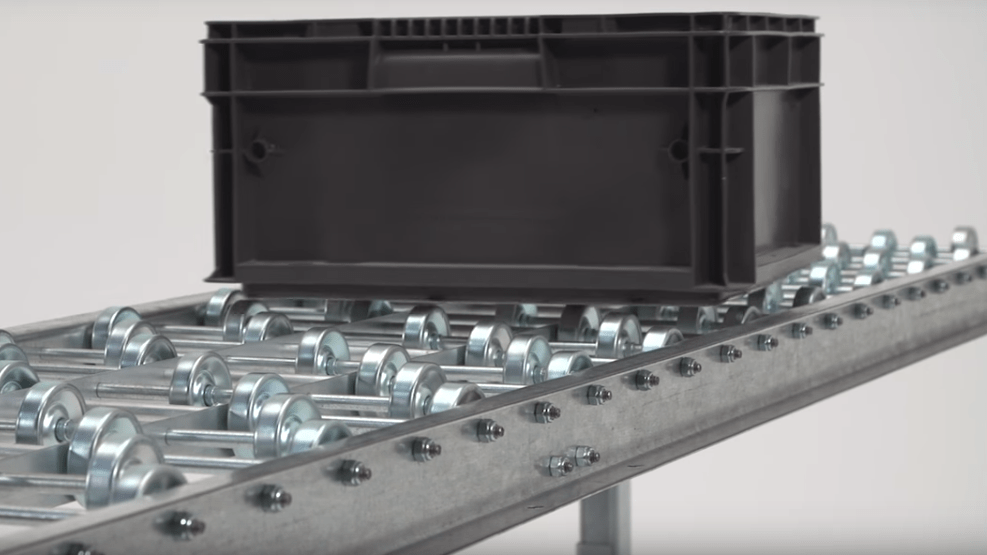

The first roller type that was ever designed was a metal cylinder which had a hinge on one end and was utilized for packing food. Gradually, this style progressed into what we know today as a gravity roller conveyor. The device made use of in a gravity roller conveyor includes a large roller (the "head") that relocates vertically backwards and forwards and also is attached to a smaller sized straight shaft through depend upon either end. This creates a press and draw force that creates the rollers to push the materials backwards and forwards the straight shaft. The larger the materials, the higher the rate of the head. The various other primary distinction in between the two types of Metalcraft Distributors is the material used to construct both. Metalcraft representatives are typically made from a durable and also solid product, such as aluminum or steel. Get top roller conveyors or see these gravity conveyors.

The layout of a Metalcraft circulation system makes it a lot more susceptible to harm if a mishap happens, which is why the heads of a lot of Metalcraft roller conveyors are made to make sure that they can be conveniently jostled. A gravity roller conveyor system on the other hand, is usually developed out of a lighter and also a lot more versatile product. Lighter products have a tendency to reduce the opportunities of damages as a result of effect as well as vibration, which is why most LVP conveyors are made from a plastic substance. There are many different manner ins which a Metalcraft Circulation System can be made use of, and also the manner in which it is developed will establish the very best means to use it. In a typical storehouse setup, the roller and also straight shaft assembly are integrated with a vehicle installed device and also a forklift or pallet crane to aid move the goods to the different sections of the storage facility. An additional preferred use of a Metalcraft circulation system is in the product packaging market.

This type of system is commonly used to move lightweight however hefty products such as canned food and also medical supplies. It is additionally used to deliver tool sized however delicate items, such as those that are stuffed inside delicate packaging such as syringes. The typical sorts of Metalcraft Distributors that are most often seen in storehouses and producing plants are the roller as well as straight shaft variations. These two systems are generally integrated with a quickstep conveyor. A fast slip conveyor is a much larger version of a gravity conveyor, and also it is capable of relocating heavier loads than either roller or straight shaft versions. A lot of suppliers that provide this sort of service additionally use strong truck placed devices that have the ability to be completely automated. Numerous representatives that use this solution even have the ability to from another location manage the motion of their installed Metalcraft roller and straight shaft devices.

The common kinds of Metalcraft Distributors can likewise be combined with other sorts of relocating tools in order to enhance their convenience and also performance. This is especially real when it involves managing conveyors. Due to the fact that these gadgets are normally constructed of steel, they can be made use of to transfer items of all weights and sizes. Given that they likewise have motors as well as electronics, they are likewise very effective in running both throughout making procedures in addition to message handling. For companies that require the best type of product packaging, storage space, or taking care of conveyor, it would certainly be best to seek advice from an expert supplier to figure out which type of system would certainly be best for their procedure. Continue reading more on this here: https://www.youtube.com/watch?v=NSfsYKMLZEM.